Oxidation Ditch Fix

Issue:

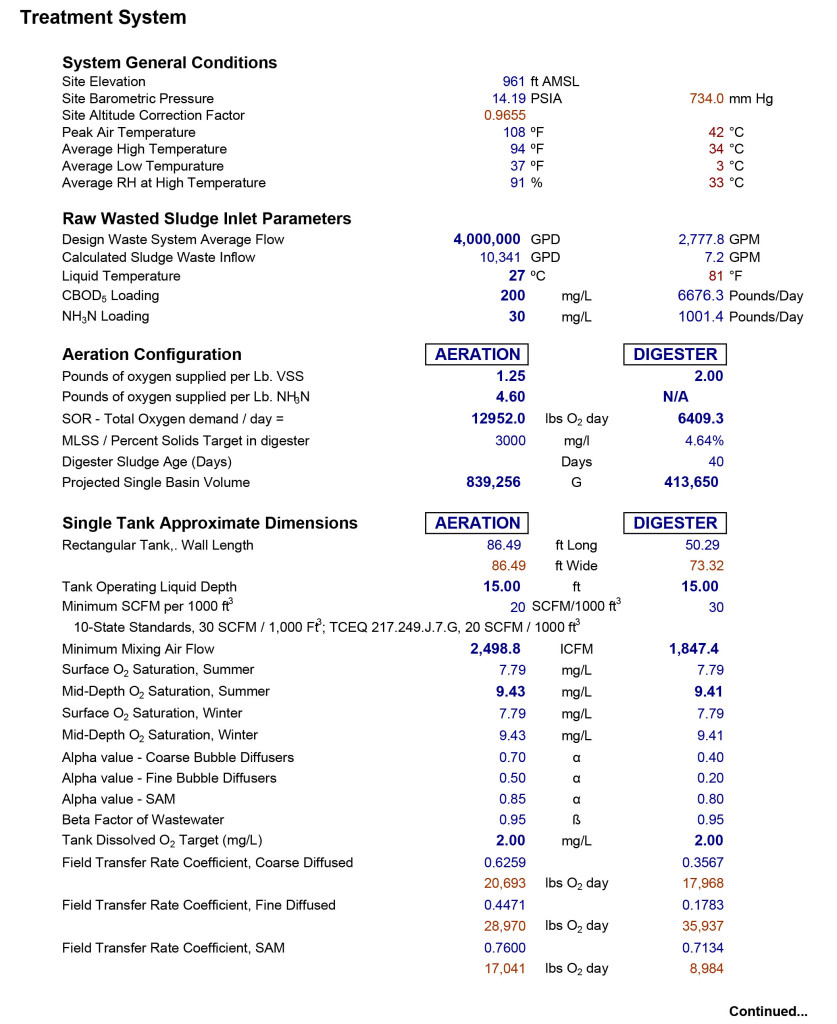

Oxidation Ditches were originally designed for small WWTPs with high TCEQ discharge limits. Apparently owners were caught by surprise when they learned their process lacked the ability to maintain their DO limits during high summer temperatures or high flows. The process begins to fail when the process exceeds 50% of their rated capacity in some instances.

Resolution:

Performance can be restored by supplementing or replacing the existing aeration approach. The objective is simply to provide adequate aeration capable of maintaining required DO levels throughout the capacity range of the process while still providing anoxic mixing.

The current TCEQ regulations favor REMOVABLE aeration and mixing technologies that DO NOT require basin dewatering. When this approach is employed redundant basins are not required. Removable components are therefore the least cost alternative upgrading or converting failing oxidation ditch WWTPs.

Two Paths for Restoring DO Levels

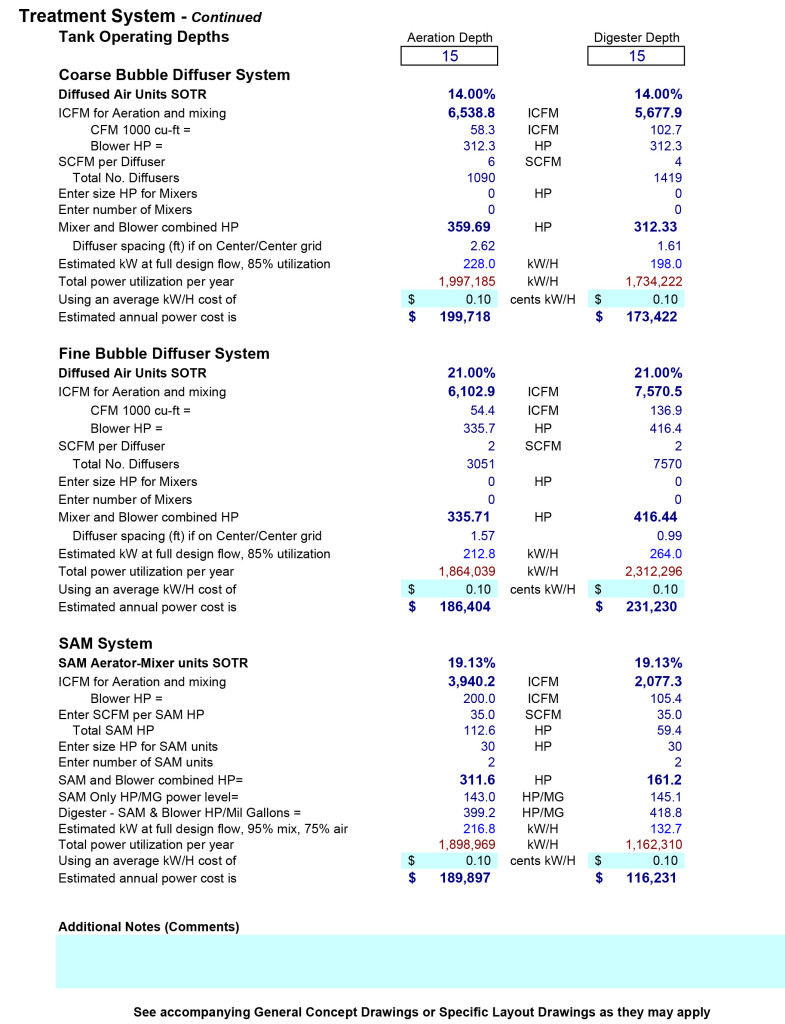

Additional Aeration Supply – In cases when the application can be further utilized with supplemental aeration only, then installation of Submersible Aeration Mixers of SAMs combined with blowers are sufficient. Smaller applications are best suited for VFD controlled PD blowers.

Process Conversion – When the capacity of the WWTP requires a large scale capacity adjustment then additional SAMs, larger blowers and a BER submersible mixer(s) are required. The BER is a submersible mixer designed to provide hydraulic velocity. Both the SAM and BER meet the revised TCEQ 317 revisions for removable aeration devices thereby eliminating the need for redundant basins. Anoxic zones are retained.