Oxidation Ditch Fix

Oxidation Ditch Fix: Upgrade Paths to Restore DO Levels

Issue: Why Oxidation Ditches Struggle

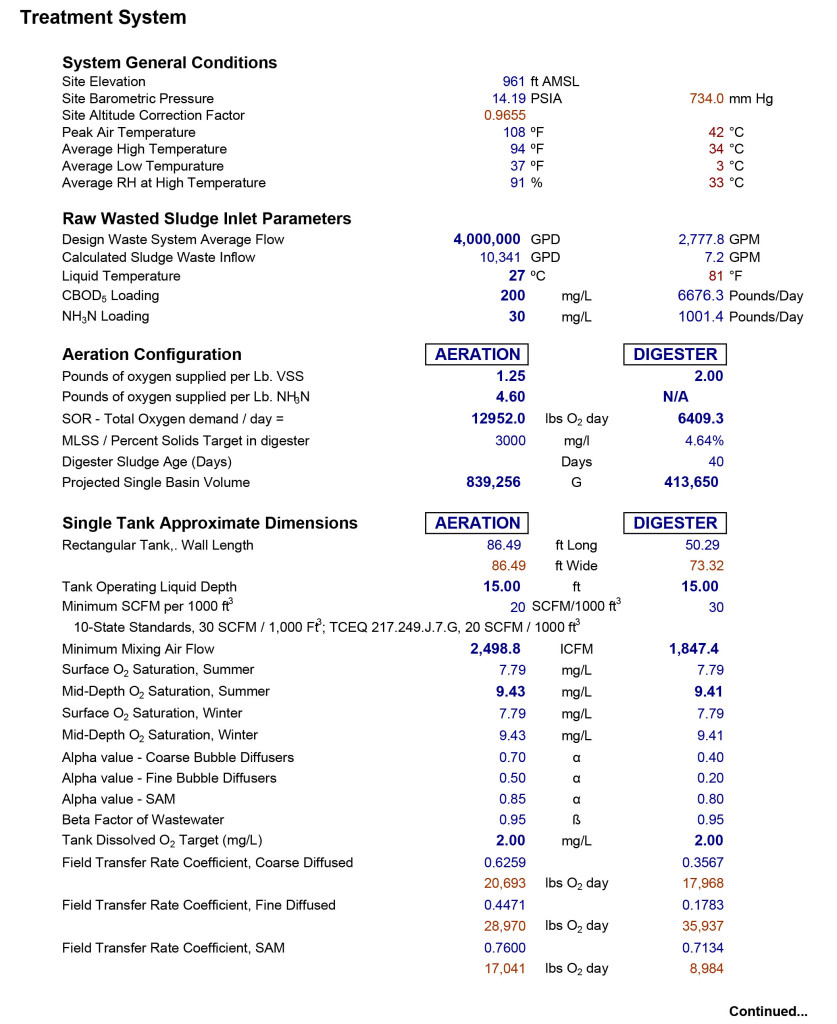

Oxidation ditches were originally designed for smaller wastewater treatment plants with higher discharge limits. Many municipalities later discovered that these systems struggle to maintain dissolved oxygen (DO) levels during peak summer temperatures or when flows approach design capacity. In some cases, performance begins to fail at just 50% of the rated capacity.

Low DO not only impacts effluent quality but also increases energy costs and operational headaches. That’s where a proven oxidation ditch fix can restore capacity and extend the life of your existing infrastructure.

To effectively address these challenges, it’s essential to implement strategies that can help to restore DO levels in your oxidation ditch systems.

Resolution: Two Proven Paths for Restoring DO Levels

Performance can be restored by supplementing or replacing the existing aeration approach. The objective is simply to provide adequate aeration capable of maintaining required D.O. levels throughout the capacity range of the process while still providing anoxic mixing.

The current TCEQ regulations favor REMOVABLE aeration and mixing technologies that DO NOT require basin dewatering. When this approach is employed redundant basins are not required. Removable components are therefore the least cost alternative upgrading or converting failing oxidation ditch wastewater treatment plants.

1. Additional Aeration Supply

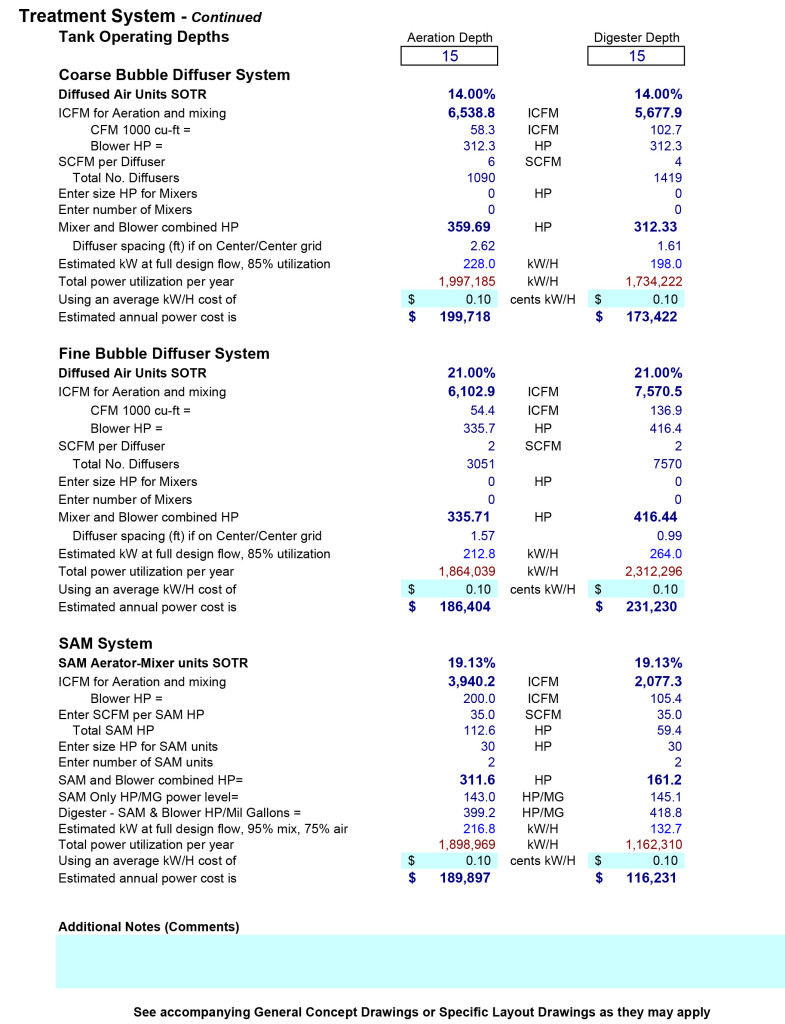

When the basin structure is sound and only supplemental oxygen is needed, Submersible Aeration Mixers (SAMs) combined with efficient blowers are often the simplest fix.

- SAMs are “drop-in” units that provide mixing with or without airflow.

- They reduce rag buildup and eliminate grit settling.

- For smaller systems, VFD-controlled PD blowers (such as United Blower Inc.) offer a cost-competitive solution.

- For higher efficiency, the APG-Neuros Turbo Blower can reduce energy costs by up to 50%.

2. Process Conversion

When capacity limitations or stricter nutrient removal requirements demand more, Vision Equipment designs full oxidation ditch conversions:

- Directional flow control with BER submersible mixers to maintain hydraulic velocity.

- Fine bubble aeration with disk diffuser grids (for basins 8’ deep or less).

- SAMs for deeper basins, providing high mixing energy from the basin floor up.

- Efficient blower packages sized to your performance requirements.

Both approaches are TCEQ 317 approved as removable aeration technologies—meaning no need for redundant basins or costly dewatering.

Benefits of an Oxidation Ditch Upgrade

- Restored DO levels across the full capacity range.

- Anoxic zones retained, enabling nitrification/denitrification for nutrient removal.

- Reduced grit settling and better sludge management.

- Energy savings through modern aeration and blower technologies.

- Single-source responsibility for design, equipment, and support.

Proven Performance in Texas

With over 20 years of installed history across Texas, Vision Equipment’s oxidation ditch conversions have consistently delivered measurable results:

- Lower effluent ammonia and BOD levels.

- Energy savings of 30–50% compared to legacy systems.

- Long-term reliability with minimal maintenance.

Ready to Fix Your Oxidation Ditch?

Don’t let seasonal DO shortages or failing aeration limit your plant’s capacity. Vision Equipment provides a single-source oxidation ditch fix—from evaluation to installation—to restore performance and reduce operating costs.

👉 Contact a Vision Equipment Rep today to discuss the best upgrade path for your facility.