Vision Equipment Blog

How Automated Chemical Dosing Took the Guesswork Out of Municipal Water Treatment

If you work in municipal water treatment, you know the daily balancing act: keeping water quality high while trying to keep operational costs low. It’s rarely a smooth ride. Raw water conditions change, turbidity spikes, and suddenly your standard chemical dose isn’t cutting it anymore.

This was exactly the situation facing a recent municipal client of Vision Equipment. They were dealing with the classic headaches of manual chemical dosing—over-treating in some windows, under-treating in others—and it was costing them both money and sleep.

Here is how the switch to automated chemical dosing using LowDose™ Software changed their operation, not just on a spreadsheet, but on the plant floor.

The Problem: The “Set and Forget” Myth

For years, many operators have had to rely on jar tests and historical knowledge to set coagulant feed rates. The problem? Water doesn’t care about history. When a storm hits or the source water shifts, a static dose becomes inefficient almost instantly.

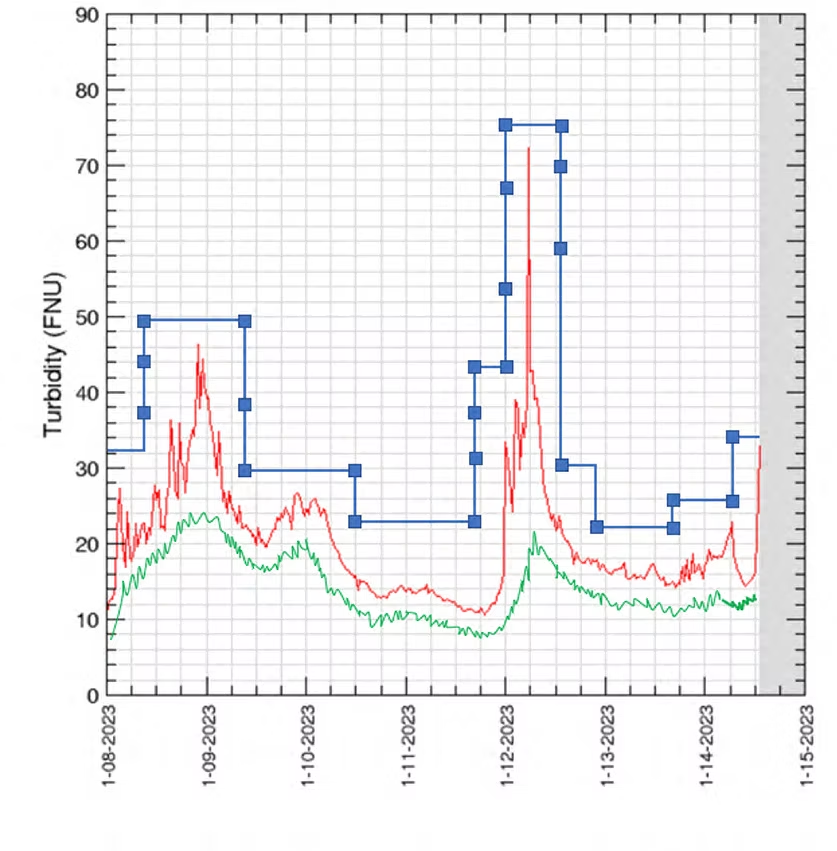

Above: This chart illustrates the “Step and Wait” reality of manual dosing. Notice how the Blue Line (Manual Dose) stays high long after the turbidity (Red Line) has dropped? That gap between the Blue and Green lines isn’t just data—it’s wasted budget.

The facility in question was struggling with:

- Inconsistent Filter Performance: Filter run times were shorter than they should have been, leading to frequent backwashing.

- Chemical Waste: To be safe, operators often default to slightly overdosing. It guarantees compliance, but it burns through budget rapidly.

- Operator Fatigue: Constantly monitoring and tweaking feed rates manually is tedious and prone to human error.

The Solution: Real-Time Automated Chemical Dosing Intelligence

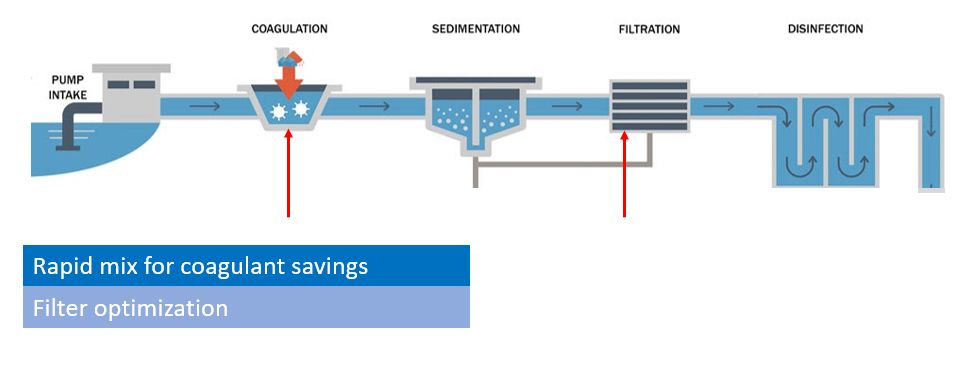

The plant managers decided to trial LowDose Software. Unlike complex AI systems that require a year’s worth of data training before they become useful, LowDose is analyzer-driven. It works off Zeta Potential—essentially the electrical charge of the particles in the water.

Think of automated chemical dosing as cruise control for chemical dosing. The software reads the current charge of the water in real-time and adjusts the coagulant feed immediately to neutralize it. It doesn’t guess based on what happened last month; it reacts to what is happening right now.

The Results: Immediate ROI

Once the automated chemical dosing system was live, the change was night and day. The software didn’t just “work”; it fundamentally shifted how the plant operated.

1. Chemical Usage Dropped

Because the system automatically dialed back the coagulant when the water cleared up, the plant stopped wasting chemicals. They weren’t paying for “just in case” overdosing anymore.

2. Filters Breathed Earlier

With the chemistry optimized, the floc formed better. This meant the filters didn’t clog as quickly. Filter run times extended significantly, which meant less backwash water used and less energy spent pumping it.

3. The “Sleep at Night” Factor

Perhaps the biggest win wasn’t on the balance sheet—it was for the team. Operators no longer had to hover over the feed pumps during a rain event. They trusted the system to catch the swing in turbidity.

See it in Action

You can look at specs all day, but out in the field, the only thing that matters is results. We’ve seen plants struggle for years with swinging turbidity and blown budgets, only to turn it around inside a few months. Here is what that looks like in the real world:

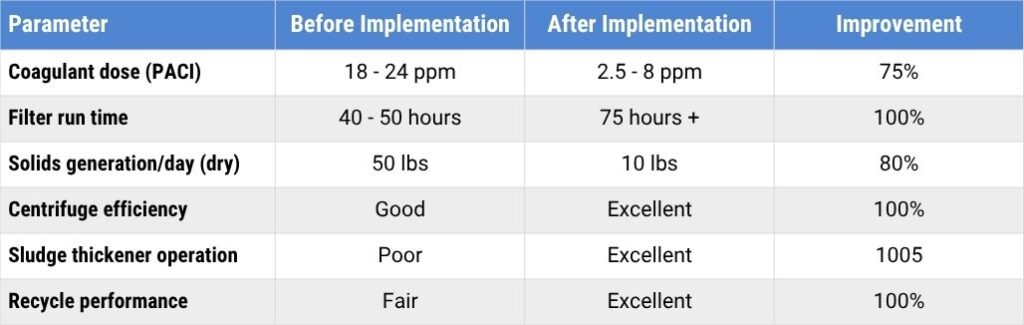

Breckenridge Water Treatment Plant Case Study

Breckenridge was dealing with a headache familiar to many of us: raw water quality that wouldn’t sit still. Manual dosing just couldn’t keep up without constantly overshooting or undershooting.

The Turnaround:

- Chemical use dropped by 32%. That’s real money staying in the budget.

- Consistency. The operators aren’t chasing spikes anymore; the system catches them.

- Compliance. The water quality stabilized, keeping the regulators happy.

Salisbury Water Treatment Facility

Salisbury was bleeding money on chemicals and burning out their team with constant manual adjustments. It was an efficiency nightmare.

The Turnaround:

- 20% Drop in Chemical Costs.

- 30% Less Labor. That’s hours given back to the operators to focus on maintenance and other critical tasks instead of babysitting a pump.

- Simplified Compliance. When the dose is right, the reporting gets a whole lot easier.

Sustainability (and Common Sense)

Folks like to use big words when talking about sustainability, but for us, it really comes down to being good stewards of what we have. LowDose helps you run a cleaner, tighter ship, which looks good to the city council and the community.

- Less Chemical Waste (And Less Hauling): You aren’t just trucking in loads of chemicals; you’re also filling dumpsters with sludge. By cutting the overdose, you reduce the volume of sludge you have to pay to haul off.

- Energy Efficiency: Better floc formation means your filters run longer. Longer runs mean fewer backwash cycles and less electricity used to pump that water.

- Measurable Data: When the city asks how you’re improving the plant’s environmental footprint, you’ll have the hard numbers to show them.

Installation: No need to tear the plant apart

I know what you’re thinking: “This sounds great, but I can’t afford to shut down for a retrofit.”

The good news is, you don’t have to. We know that in this industry, downtime isn’t an option. LowDose is designed to layer on top of what you already have.

- It plays nice with your existing gear. We integrate with your current infrastructure.

- Fast setup. We aren’t talking about months of construction. We get in, get it calibrated, and get out of your way.

We don’t leave you hanging. We train your guys on how to use it until they are comfortable. We stick around to make sure it works the way we said it would.

Common Questions (FAQs)

What does LowDose actually automate in a water plant?

It automates the decision-making for your chemical feed rates. Instead of an operator looking at a jar test and guessing, the software reads the water’s particle charge (Zeta Potential) and adjusts the pumps automatically to hit the sweet spot.

Do I have to replace my current SCADA or feed pumps?

Likely not. LowDose is built to integrate with most municipal setups. We aren’t trying to reinvent your wheel; we just want to make it roll smoother. It works as a layer of intelligence on top of your existing SCADA.

How long is the ROI for an automated dosing system?

Most plants see the chemical savings pay for the system within the first year, sometimes in just a few months. When you factor in the labor savings and increased filter efficiency, the math makes sense pretty quickly.

I need more details for my team. Do you have a LowDose brochure?

Absolutely. If you need to dig into the engineering specs or want to show your city council the hard numbers from other plants, we have a complete packet ready for you:

- LowDose General Brochure: A deep dive into the hardware, PID loop controls, and SCADA integration.

- Breckenridge Case Study: See the data on how they achieved a 75% reduction in coagulant dose and doubled their filter run times.

- Salisbury-Rowan Case Study: Read how this facility reduced solids generation by 60% and optimized their ballasted sand clarifier.

The Bottom Line

For this municipality, LowDose wasn’t just a tech upgrade; it was a stress reliever. The ROI is projected to be achieved in under two years based on chemical and energy savings alone, but for the plant manager, the real value is consistency.

The system proved that you don’t need to replace your entire infrastructure to get better results—sometimes, you just need a smarter way to drive the equipment you already have.

Ready to stop guessing?

If you are tired of chasing set points and want a system that handles the heavy lifting for you, let’s talk. We can look at your current setup and show you exactly where LowDose can save you money—and save your operators a lot of stress.