Vision Equipment Blog

Jaeger-Aeration OxyLift System: Redundancy and Maintainability

Eliminate basin dewatering for diffuser maintenance. Improve uptime. Reduce O&M burden.

The Jaeger-Aeration OxyLift System is transforming how wastewater treatment plants manage aeration maintenance and day-to-day operational reliability. As a fully retrievable diffuser solution, OxyLift allows operators to raise and service diffuser racks without draining the basin—eliminating costly downtime, confined-space entry, and reliance on heavy lifting equipment.

Paired with Jaeger-Aeration’s high-efficiency OxyStrip fine-bubble diffusers, the system provides superior oxygen transfer, built-in redundancy, and long-term maintainability that today’s treatment facilities expect.

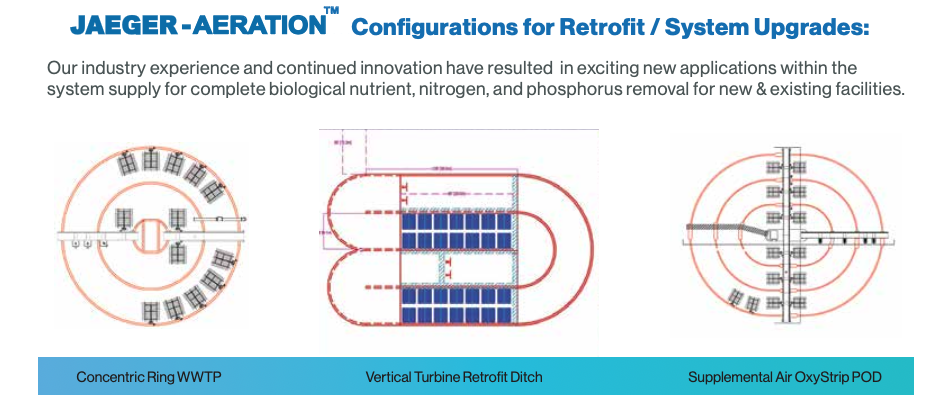

Whether you’re retrofitting existing basins or planning future expansions, the OxyLift + OxyStrip combination delivers the flexibility, safety, and long-term performance wastewater plants need to stay resilient.

What Is a Retrievable Aeration System?

Unlike traditional fixed-grid aeration systems, a retrievable aeration system is engineered for quick, safe, above-water access. With the OxyLift System, each diffuser rack can be raised and lowered directly from the bridge or walkway—no basin dewatering and no confined-space entry required.

Attached to each rack, the OxyStrip fine-bubble diffuser maximizes oxygen transfer, reduces fouling, and lowers long-term maintenance demand.

How the OxyLift Retrievable Aeration System Works:

The Jaeger-Aeration OxyLift System uses a rail-mounted design that allows diffuser racks to be raised and lowered quickly from the basin walkway.

- Bridge-mounted retrieval: Racks slide along guide rails and can be lifted using a manual or motorized winch.

- Fast service times: Most racks can be pulled, inspected, and reinstalled in 2–5 minutes.

- Rack-by-rack maintenance: Operators can service one rack at a time while all others remain in operation—maintaining full aeration capacity throughout the basin.

Why Redundancy & Maintainability Matter for Aeration Systems

Today’s wastewater utilities must keep systems online 24/7 while contending with tight budgets, limited staff, and aging infrastructure. The OxyLift System is designed specifically for these operational realities.

Built-In Redundancy

With multiple diffuser racks installed per basin, operators can pull one rack for service while all others remain in full operation.

No shutdowns. No partial process failures. Just continuous, reliable treatment.

Easy & Safe Maintenance

Traditional diffuser maintenance often requires cranes, basin dewatering, and confined-space procedures. The OxyLift System eliminates those barriers:

- No heavy-duty cranes required – Each rack weighs ~700 lbs and can be handled with the same equipment used for typical submersible pumps.

- Bridge-mounted winch operation – Racks can be raised directly from the walkway, reducing logistics, cost, and staff requirements.

- No confined-space entry – All work is performed safely from the surface—no permits, PPE, or standby personnel required.

Together, these features make inspections and spot maintenance faster, safer, and far less dependent on contractors.

Case Studies: Real-World OxyLift Installations

These municipalities have already made the switch—and their results speak volumes:

Hays, Kansas

The City of Hays installed the Jaeger-Aeration OxyLift System to improve aeration performance and enhance maintenance safety. The bridge-mounted rack design allowed them to retrofit the basin without structural modifications.

- Enabled real-time maintenance with basins in operation

- Improved safety by eliminating confined-space access

- Cut maintenance time to under 5 minutes per rack

📖 Case Study: Hays, KS – Jaeger-Aeration / 🎥 Project Video: Hays, KS Case Study

Farmington, Missouri

Farmington modernized its aeration system and made a strategic investment in long-term energy efficiency. After installing the OxyLift Retrievable Aeration System with OxyStrip fine-bubble diffusers, the plant recorded substantial reductions in blower kWh usage while maintaining treatment performance.

- $80,000 annual energy savings

- Reduced blower power demand through high-efficiency fine-bubble diffusion

- Enabled smarter O&M practices without draining basins or entering confined spaces

“Less than one week of construction for an aeration basin retrofit resulted in $80,000 in annual energy savings for this Missouri wastewater treatment plant.” – Farmington, MO NE WWTP | 2023 Wastewater Digest Top Projects (click to read full article)

These improvements not only improved maintainability but also helped the facility reduce its long-term power demand, offering a strong return on investment—both operationally and financially.

📖 Case Study: Farmington, MO – Jaeger-Aeration / 🎥 Video: Case Study for Wastewater Digest

Freeburg, Illinois

Freeburg upgraded its aeration process with OxyLift and OxyStrip diffusers to avoid contractor-heavy maintenance and reduce service interruptions.

- Installed with existing tank geometry—no structural changes needed

- Avoided expensive crane rental and dewatering logistics

- Created a safer, more autonomous maintenance workflow

📖 Case Study: Freeburg, IL – Jaeger-Aeration / 🎥 Project Video: Freeburg, IL Case Study

Safety Advantages: No Confined-Space Entry Required

Confined-space entry is not only hazardous—it’s costly, labor-intensive, and heavily regulated. Permits, specialized PPE, rescue personnel, and procedural delays can turn even basic diffuser maintenance into a major operational burden.

With the OxyLift System, all diffuser inspection and servicing occurs from the surface, eliminating confined-space entry entirely and keeping operators safe while simplifying regulatory compliance.

- No permit-required confined space entry

- No need for respiratory protection or extraction teams

- Enables quick spot checks without disrupting process flow

OxyLift vs. Traditional Fixed Diffuser Systems

Here’s what makes OxyLift a smarter choice for wastewater plants focused on reliability and long-term maintainability:

| Feature | Traditional Fixed Diffuser | Jaeger-Aeration OxyLift System |

| Maintenance Access | Requires basin to be drained | Full-basin access; no dewatering |

| Downtime | Often 1–2 days | Minutes per rack; zero downtime |

| Safety Risk | Requires confined space entry | No confined space entry |

| Redundancy | All or nothing | Multi-rack system allows selective removal |

| Installation Equipment | Cranes often needed | None—bridge-mounted access |

| Staffing Needs | Contractors or specialized crews | In-house team can maintain |

| Geometry Compatibility | Often limited | Adapts to existing basin layout |

The Role of OxyStrip in the OxyLift System

The OxyStrip fine-bubble diffusers used in OxyLift installations provide precise airflow distribution and high oxygen transfer for demanding wastewater applications. Key advantages include:

- Fine-bubble diffusion for high oxygen transfer efficiency (OTE/SOTE)

- Low fouling design that minimizes clogging in biological environments

- Long service life with consistent headloss control

- Multiple lengths available to match basin geometry and process requirements

Together, OxyLift + OxyStrip form a retrievable aeration system that is easier to maintain while delivering superior long-term performance.

📄 Product Data Sheet: OxyStrip Buyers Guide / 🎥 Product Video: OxyStrip Slider

Why OxyLift Is Ideal for Texas Wastewater Facilities

While the case studies span Kansas, Missouri, and Illinois, the OxyLift System is exceptionally well-suited for Texas municipal wastewater plants, where geographic, environmental, and operational conditions present unique challenges.

Why It Works for Texas:

- Ideal for remote or rural facilities with limited crane access

- Performs reliably in high-heat, high-humidity climates

- Supports plants operating with lean staff, reducing reliance on contractors

- Helps meet stringent TCEQ safety requirements without additional labor burden

Engineering Support and Design Assistance

Working with Vision Equipment and Jaeger-Aeration means your team is supported throughout design, installation, and long-term operation. We provide:

- Custom layouts to match your basin geometry

- Technical drawings and design support

- Ongoing assistance from a team that understands wastewater challenges inside and out

Frequently Asked Questions About the OxyLift System

Does the OxyLift System require draining the basin for maintenance?

No. You can retrieve and reinstall diffuser racks while the basin remains full.

Can my in-house team handle the maintenance?

Yes. No special certifications, confined-space training, or heavy equipment are required.

How fast is diffuser rack removal?

Most racks can be retrieved and inspected in under 5 minutes.

Is the OxyLift System compatible with existing tank geometry?

In nearly all cases, yes. The system is designed to retrofit into most conventional basin layouts without structural changes.

Conclusion: Redefining Retrievable Aeration with the OxyLift System

Traditional fixed diffuser systems come with safety risks, high maintenance costs, and operational downtime that today’s treatment plants can no longer afford.

With the Jaeger-Aeration OxyLift System and integrated OxyStrip diffusers, facilities gain:

- Operational flexibility

- Enhanced safety

- Low-maintenance, high-performance aeration

For plants seeking to modernize their process, reduce annual costs, and improve maintainability, OxyLift provides a proven, practical, and operator-friendly solution.