Vision Equipment Blog

What is a Retrievable Aeration System?

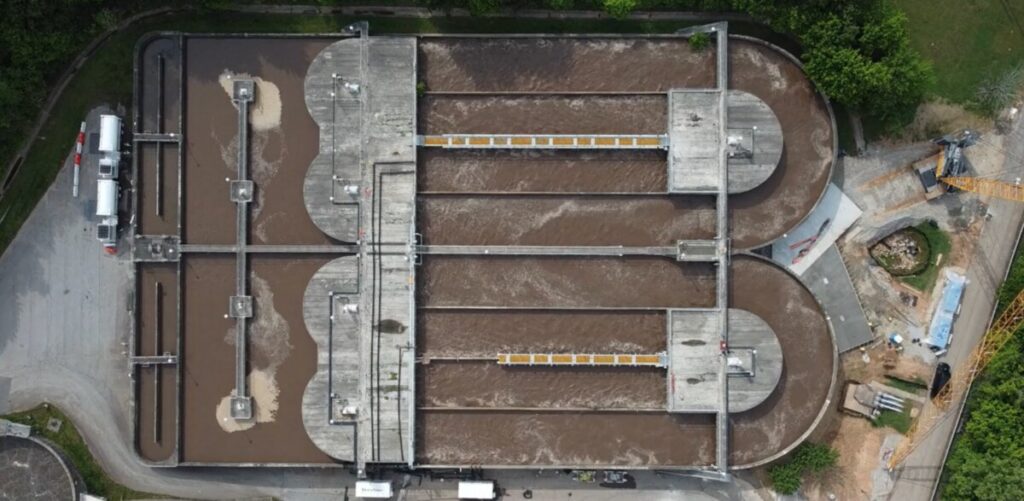

In wastewater treatment, aeration is essential for supporting biological processes that break down organic material. Traditional aeration uses diffusers fixed to the basin floor or mounted on rigid grid systems, which can be difficult to access and maintain without draining or shutting down.

A retrievable aeration system (also called a “removable diffuser system” or “retrievable diffuser grid”) is designed so that diffuser modules or racks can be removed or serviced without fully dewatering the basin or interrupting the entire treatment process. In effect, parts of the aeration system become modular and serviceable within the active basin.

How Does a Retrievable Aeration System Work?

- Modular diffuser assemblies / racks — The diffusers and part of the piping are mounted on frames or racks sized to be handled as units—lifted in and out during maintenance.

- Flexible or quick-disconnect piping — Instead of rigid welded headers, air supply lines include couplings, flexible hoses, or swivel joints to allow safe disconnection during removal.

- Hoisting or handling infrastructure — Rails, bridge gantries, cranes, hoists, or davits may be used to support movement of modules in and out of the tank.

- Leveling or floatation features — In basins with changing water depths (e.g. lagoons), floats or self-leveling mechanisms may be used to maintain correct diffuser depth.

- Zoned or redundant design — The aeration field can be zoned so that some modules can be taken offline for service while the rest remain in operation.

- Control integration — Incorporation of oxygen (DO) and redox (ORP) feedback control, blower turndown, and zoned control to dynamically adjust airflow to each module.

During maintenance, one module or rack is disconnected, lifted out, worked on (cleaned, inspected, parts replaced), and then reinserted, ideally without significant impact to ongoing treatment.

Can an Existing Plant Be Upgraded to Use Retrievable Aeration?

Many existing treatment plants are candidates for retrofitting to retrievable aeration—though it depends on site conditions and engineering. Key factors to evaluate include:

- Basin geometry & access — Sufficient headroom, access from above, clear space for maneuvering modules, and absence of obstructions are critical.

- Air header and blower capacity — Existing piping and blowers must support modular connections, flexible routing, and possibly adjusted pressure drops.

- Mixing and hydraulic performance — The retrievable layout must still ensure good mixing, avoid dead zones, and maintain solids suspension.

- Structural and support needs — Installing rails, hoist supports, or access platforms may require structural modifications.

- Control and instrumentation — Upgrading or extending DO/ORP sensors, zone valves, blower control, and SCADA logic is commonly needed.

- Cost and lifecycle tradeoffs — Upfront capital costs are higher, but the long-term payoff lies in lower maintenance disruption, easier repairs, and potential energy gains.

- Phasing and pilot testing — It’s often advisable to convert a single basin or a portion first, to validate performance before full implementation.

Benefits of a Retrievable Aeration System

Benefits

- Reduced operational downtime — Modules can be serviced while much of the system remains online, avoiding prolonged shutdowns.

- Simplified maintenance — Diffusers, membranes, and piping can be accessed under drier or safer conditions rather than submerged and buried under solids.

- Flexibility and redundancy — Portions of the aeration field can be isolated, serviced, or repositioned to match changing load profiles.

- Improved lifecycle value — Although capital cost is higher, the ease of maintenance and reduced risk of surprises often improves total cost of ownership.

- Retrofit capability — Existing basins can often be adapted without full rebuilds, enabling gradual upgrades.

- Better adaptiveness to fouling — Regular retrieval and inspection allow more frequent cleaning or replacement before fouling degrades performance.

- Energy savings — Energy efficiency is a significant issue for aeration systems. Diffused aeration technology like Jaeger Aeration’s fine bubble OxyStrip product has demonstrable results for energy reduction compared to mechanical aeration technology.

Types & Configurations of Retrievable Aeration

Some common configurations include:

- Drop-type assemblies — Diffusers mounted near one wall or in a “T” configuration, lowered or raised for servicing.

- Floating lateral header with suspended diffusers — The air header floats on the surface, while diffusers hang via hoses or suspension lines.

- Retrievable grid or rack assemblies — Modular racks (e.g. PVC or stainless frames) with diffusers and supports, designed to be lifted out.

- Floating-retrievable fine-bubble systems — Designs that combine floatation and retrievability so modules stay level despite changing water levels.

- What shapes of fine bubble membrane diffuser designs are available in today’s WWT marketplace? (source: Jaeger Aeration)

- Hybrid systems — Retrievable modules used alongside fixed diffusers or surface aerators to blend benefits or for staged implementation.

Practical Considerations & Best Practices

- Module sizing vs handling ease — Bigger modules reduce connection count but increase lifting weight and complexity.

- Coupling reliability — Couplings, swivel joints, and valves must be robust to frequent disconnection, fouling, and misalignment.

- Ease of alignment & reinsertion — Racks or modules should have guides, rails, or alignment features to ensure smooth reinstallation.

- Redundant or bypass capability — Zones should be designed so one module can be removed without starving the process of oxygen.

- Maintenance protocols — Establish regular inspection, cleaning, and removal cycles to reduce surprises.

- Material durability — Membranes, piping, seals, and structural elements should resist corrosion, abrasion, biological fouling, and chemical stresses.

- Instrumentation and sensing — Place DO, ORP, or ammonia sensors judiciously to provide actionable feedback per zone or module.

- Operational tuning — Use blower turndown, zone valves, and feedback control to modulate airflow and avoid over- or under-aeration.

- Pilot trials or reference visits — Experience in real operating conditions can reveal issues invisible in models—visit sites using retrievable systems or pilot a small section first.

When Retrievable Aeration Systems Make the Most Sense

Retrievable aeration systems are especially attractive in scenarios such as:

- Plants where basins cannot be drained easily or where outage windows are constrained.

- Facilities with aging aeration systems that are difficult to reach or maintain.

- Treatment systems requiring flexibility—phased upgrades, future expansion, or variable loads.

- Lagoons or basins with variable water levels or mixed-use zones.

- Applications where serviceability, inspection, and modular replacement are key drivers.

They may be less appropriate in very deep basins, highly fouling environments, or when simplicity and lowest capital cost outweigh the benefits of flexibility.

Summary

Retrievable aeration systems bring modularity and serviceability to the core aeration function of biological wastewater treatment. By making diffusers and their supporting assemblies accessible, treatment plants can reduce downtime, ease maintenance, and increase flexibility. While the upfront cost and engineering complexity are greater, the long-term benefits often make retrievable designs worthy of serious consideration—especially for plants planning to upgrade, retrofit, or improve operational resilience.